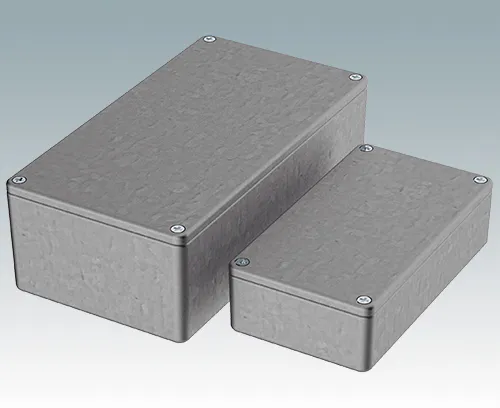

What are Large Diecast Enclosures

Large diecast enclosures are protective housings, typically made from metal, that encase and safeguard electronic components, electrical equipment, and other sensitive devices. These enclosures are manufactured using a die casting process, where molten metal is injected into a mold under high pressure. This process allows for complex shapes and designs, ensuring a precise and robust final product. The primary function of these enclosures is to shield internal components from environmental factors such as moisture, dust, impact, and electromagnetic interference (EMI), ensuring the longevity and reliable performance of the housed equipment. They are essential in various industries, offering a reliable solution for protecting valuable electronics in harsh conditions. Choosing the right enclosure is crucial, as it directly impacts the lifespan and functionality of the equipment it houses.

Materials Used in Large Diecast Enclosures

The choice of material significantly influences the performance and suitability of a large diecast enclosure. The most commonly used materials are aluminum and zinc, each offering unique advantages. Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and efficient heat dissipation properties. Zinc, on the other hand, provides superior mechanical strength and is often selected when enhanced durability is a critical requirement. Besides these primary materials, enclosures can also be made using other materials depending on specific needs, offering various performance characteristics and cost considerations. The selection of the right material is vital to ensure the enclosure meets the specific demands of its operational environment and the housed equipment.

Aluminum

Aluminum diecast enclosures are widely used due to their lightweight nature and high resistance to corrosion, making them ideal for outdoor applications or environments with high humidity. Aluminum’s excellent thermal conductivity helps to dissipate heat generated by internal components, preventing overheating and extending the lifespan of the equipment. Moreover, aluminum is easily customizable, allowing for various surface finishes, including powder coating and anodizing, to enhance appearance and further improve protection against the elements. The versatility and performance benefits make aluminum a prevalent choice for various industries where reliability and durability are paramount.

Zinc

Zinc diecast enclosures provide exceptional mechanical strength and robustness, suitable for applications where the enclosure may be subject to impact or physical stress. Zinc offers excellent shielding against electromagnetic interference (EMI), making it an ideal choice for sensitive electronic devices that must operate without interference. Zinc enclosures also exhibit good corrosion resistance, although often enhanced through surface treatments like chromate conversion coatings or powder coating. This combination of strength, shielding capabilities, and corrosion resistance makes zinc enclosures suitable for demanding industrial environments where equipment protection is critical. The inherent properties of zinc ensure the equipment’s long-term operational reliability under challenging conditions.

Other Materials

While aluminum and zinc are the most common, other materials can be used for large diecast enclosures, depending on specific needs. These may include magnesium alloys for lightweight applications requiring high strength, or specialized alloys to meet specific chemical resistance requirements. The selection of these alternative materials depends on the specific demands of the application, considering factors like operating temperature, chemical exposure, and mechanical stress. Such custom materials offer tailored solutions for unique operational challenges, ensuring optimal performance and protection of the housed components in specialized industries and environments.

Design and Features of Large Diecast Enclosures

The design and features of large diecast enclosures are crucial to ensuring the effective protection and functionality of the equipment housed within. These features contribute to the enclosure’s ability to withstand environmental factors, provide adequate space, and facilitate easy access for maintenance and installation. The dimensions, ingress protection ratings (IP ratings), and surface finishes are key aspects that influence the enclosure’s performance and its suitability for various applications. Careful consideration of these elements is essential when selecting or designing an enclosure to meet specific operational requirements and maintain the longevity and reliability of the housed equipment.

Size and Dimensions

Size and dimensions are critical considerations for large diecast enclosures, directly affecting the internal space available for components and the overall footprint of the equipment. Enclosures are available in a wide range of sizes to accommodate diverse equipment configurations, from small control units to large power distribution systems. The internal dimensions must provide sufficient space for the components, wiring, and any necessary cooling systems, allowing for easy assembly, maintenance, and future upgrades. External dimensions are also vital, considering available space and the need for integration with other equipment or systems. Proper size selection ensures not only the protection of the equipment but also optimal operational efficiency and accessibility.

Ingress Protection Ratings (IP Ratings)

Ingress Protection (IP) ratings are international standards that define the level of sealing effectiveness of electrical enclosures against intrusion from foreign bodies (dust, dirt) and moisture. The IP rating consists of two numbers; the first indicates the level of protection against solid objects, and the second indicates the level of protection against liquids. For instance, an IP65-rated enclosure is dust-tight (6) and protected against water jets (5). Higher IP ratings, such as IP67 or IP68, indicate increased protection against water ingress, making them suitable for outdoor or harsh industrial environments. Choosing an enclosure with an appropriate IP rating is critical to ensuring the housed equipment remains protected from environmental hazards, preventing damage and maintaining operational reliability. The IP rating ensures the enclosure provides the required level of protection for the intended application.

Surface Finishes

Surface finishes play a crucial role in the performance, appearance, and longevity of large diecast enclosures. Common finishes include powder coating, which provides excellent corrosion resistance and a durable, aesthetically pleasing surface, and anodizing, frequently used for aluminum enclosures to enhance corrosion resistance and wear resistance. Other options include painting, which offers a wide range of colors and finishes, and specialized coatings that provide enhanced protection against specific chemicals or environmental conditions. These finishes not only protect the enclosure material from environmental factors but also enhance the enclosure’s aesthetic appeal and can aid in identifying equipment or providing specific functional properties, such as improved electrical conductivity or EMI shielding. Proper surface finishing is vital for ensuring the longevity and reliable operation of the enclosure in its intended environment.

Applications of Large Diecast Enclosures

Large diecast enclosures find widespread application across various industries, serving as protective housings for critical electronic and electrical equipment. Their robust construction, durability, and environmental resistance make them ideal for applications where equipment must operate reliably in challenging conditions. Key applications include industrial electronics, outdoor equipment, and telecommunications, where the enclosures protect sensitive components from physical damage, moisture, dust, and electromagnetic interference, ensuring the consistent and dependable performance of housed equipment. The versatile nature of these enclosures, along with their customization options, makes them suitable for a wide array of industry-specific needs, contributing to the protection and longevity of critical infrastructure.

Industrial Electronics

In industrial electronics, large diecast enclosures are widely used to house control systems, sensors, and power distribution units. These enclosures protect sensitive electronic components from harsh industrial environments, including exposure to dust, chemicals, and temperature fluctuations. They ensure the reliable operation of critical equipment in manufacturing plants, processing facilities, and automation systems. The enclosures are often designed to meet specific ingress protection (IP) ratings to withstand the rigors of industrial settings. These enclosures are designed to facilitate easy access for maintenance, incorporating features such as hinged doors and removable panels. The use of large diecast enclosures in industrial electronics significantly contributes to minimizing downtime and ensuring operational efficiency.

Outdoor Equipment

Large diecast enclosures are essential for protecting outdoor equipment such as traffic control systems, security cameras, and telecommunications infrastructure. These enclosures are designed to withstand harsh weather conditions, including rain, sunlight, extreme temperatures, and wind. With high IP ratings, they prevent water and dust ingress, ensuring the longevity and reliable operation of sensitive electronics. The enclosures also offer protection against vandalism and physical damage, safeguarding the equipment from external threats. The use of corrosion-resistant materials like aluminum or zinc further enhances durability, making them well-suited for long-term outdoor installations. These robust enclosures are critical for maintaining essential services in outdoor environments.

Telecommunications

The telecommunications industry extensively utilizes large diecast enclosures to house various equipment, including base stations, signal amplifiers, and network devices. These enclosures protect sensitive telecommunications equipment from environmental factors and physical damage, ensuring reliable network operations. The enclosures often include features like integrated heat sinks for thermal management and EMI shielding to minimize interference, contributing to the performance of wireless networks. As the demand for high-speed data transmission increases, the need for robust, reliable enclosures becomes even more critical, ensuring that telecommunications infrastructure remains operational under various challenging conditions. The selection of the appropriate enclosures is essential to protect and extend the life of vital telecommunications equipment.

Advantages of Using Large Diecast Enclosures

The use of large diecast enclosures offers several significant advantages, including enhanced durability and protection, efficient heat dissipation, and extensive customization options. These benefits contribute to the overall reliability, longevity, and performance of housed equipment. The robust construction and environmental resistance of these enclosures safeguard sensitive electronic components, reducing downtime and maintenance costs. The ability to customize the enclosures ensures that they meet specific application requirements, providing a tailored solution for protecting valuable equipment in various industries. The integration of these features highlights the importance of choosing the right enclosure to enhance overall performance and ensure the long-term operational success of the housed components.

Durability and Protection

Large diecast enclosures are renowned for their exceptional durability and superior protection against environmental factors. The robust construction of diecast enclosures provides a high level of resistance to impact, vibration, and physical damage, ensuring the housed equipment remains safe under demanding conditions. Furthermore, they offer excellent protection against moisture, dust, and other contaminants, extending the lifespan of the electronic components inside. Diecast materials, such as aluminum and zinc, offer inherent resistance to corrosion, enhancing the enclosure’s ability to withstand harsh environments. This durability makes diecast enclosures an ideal choice for applications where equipment must perform reliably in challenging settings, reducing the risk of equipment failure and associated downtime.

Heat Dissipation

Efficient heat dissipation is a critical advantage of large diecast enclosures, particularly those made from aluminum. Aluminum’s high thermal conductivity allows for effective transfer of heat away from internal components, preventing overheating and extending the lifespan of the housed electronics. Many enclosures incorporate design features such as integrated heat sinks or finned surfaces to further enhance heat dissipation. Effective thermal management is essential for maintaining optimal performance and preventing equipment failure, especially in applications where high-powered components are used. The ability to dissipate heat efficiently makes large diecast enclosures well-suited for applications that require consistent and reliable operation in various conditions, thus reducing the risk of equipment failure.

Customization Options

Large diecast enclosures offer extensive customization options to meet specific application requirements. These include various sizes, shapes, and mounting configurations, providing flexibility in design and integration. The enclosures can be tailored with custom cutouts, holes, and connectors to accommodate specific components and wiring needs. Furthermore, a wide range of surface finishes, including powder coating, anodizing, and painting, can be applied to enhance the appearance and provide additional protection against corrosion and environmental factors. These customization options enable users to create enclosures that perfectly match their requirements, maximizing functionality and performance while ensuring a professional appearance. This flexibility is especially valuable in specialized applications requiring precise specifications.

How to Choose the Right Large Diecast Enclosure

Choosing the right large diecast enclosure requires careful consideration of several key factors, including application requirements, environmental conditions, and budget constraints. Making informed decisions in these areas ensures that the selected enclosure provides the necessary protection and functionality for the housed equipment. Proper assessment of these elements helps identify the most suitable enclosure, maximizing the performance and longevity of the equipment. This careful approach ensures that the chosen enclosure meets all the demands of its operating environment, maintaining the reliability and efficiency of the entire system.

Consider Your Application

The first step in choosing the right large diecast enclosure is to consider the specific requirements of your application. Identify the type and size of the components that need to be housed, ensuring that the enclosure provides sufficient internal space. Evaluate any special features required, such as heat dissipation, EMI shielding, or mounting options. Determine the level of protection needed against environmental factors such as moisture, dust, and impact. Consider the operational environment and the equipment’s intended use, as this will influence the choice of material, IP rating, and surface finish. A thorough understanding of application-specific requirements will lead to the selection of an enclosure that provides optimal protection and performance.

Assess Environmental Conditions

Evaluating environmental conditions is crucial when selecting a large diecast enclosure. Consider the operating temperature range, as extreme temperatures may require specific materials or thermal management solutions. Assess the presence of moisture, dust, corrosive chemicals, or other environmental hazards that could affect the enclosure or the equipment inside. Determine the level of ingress protection (IP rating) needed to protect against these hazards. For outdoor applications, factor in exposure to sunlight, UV radiation, and potential physical damage. Ensure the chosen enclosure materials and finishes are appropriate for the environment. A thorough environmental assessment helps guarantee that the enclosure provides adequate protection, extending the lifespan of the equipment and ensuring reliable performance in all conditions.

Evaluate Budget and Cost

Budget and cost considerations play an essential role in selecting the right large diecast enclosure. Establish a clear budget to guide your choices, balancing performance requirements with financial constraints. Consider the initial cost of the enclosure and the long-term costs associated with maintenance, repairs, and potential equipment failure. While investing in higher-quality materials and features may increase the upfront cost, it often leads to greater durability and reduced maintenance costs over the long term. Evaluate the total cost of ownership, including factors such as material, finish, and customization options. Prioritize the key features required for your application and choose an enclosure that offers the best balance of performance, protection, and cost-effectiveness to ensure long-term value and operational efficiency.