Design Phase

The creation of a NASCAR diecast car is a fascinating process, beginning with meticulous design and ending with a miniature replica ready for display or collection. This journey involves several complex stages, each requiring precision, skill, and advanced technology. The design phase is crucial, setting the foundation for the entire manufacturing process. It involves detailed planning, from the initial concept to the final blueprint, ensuring that every aspect of the car is accurately represented. The accuracy of the design directly impacts the realism and collectability of the finished product, making this initial phase incredibly important for the success of the diecast model.

Creating the Initial Design

The process commences with the creation of the initial design. This step involves gathering references such as photographs, blueprints, and dimensions of the actual NASCAR race car. Designers use this information to create a preliminary 3D model of the diecast car. This model serves as the foundation for all subsequent design and manufacturing stages, establishing the car’s overall shape, proportions, and key features. Accuracy at this stage is vital to ensure the final diecast car closely mirrors the real-life counterpart. The initial design captures the essence of the race car, preparing it for the detailed development that follows. Careful consideration is given to every curve, angle, and detail to ensure authenticity.

Digital Design Software

Once the initial design is ready, the next step is to refine it using advanced digital design software. Programs such as CAD (Computer-Aided Design) are essential tools for this phase. Designers use these software applications to meticulously model every aspect of the diecast car, from the body panels and chassis to the interior details, such as the dashboard and seats. The software allows for precise measurements, adjustments, and modifications, ensuring that every component fits together perfectly. Through this process, designers can also visualize the car from multiple angles and simulate various aspects, such as aerodynamics and structural integrity, before the manufacturing stage begins. This ensures that the final product is a highly accurate and detailed representation of the real NASCAR race car.

Model Prototyping

With the digital design complete, the next crucial step is model prototyping. This involves creating physical prototypes of the diecast car using various methods, such as 3D printing or CNC machining. These prototypes allow designers and manufacturers to assess the design’s feasibility and identify any potential issues before mass production begins. The prototypes provide a tangible representation of the car, enabling them to evaluate its shape, size, and overall aesthetic appeal. During this phase, adjustments and refinements are made based on the feedback from the prototypes, ensuring that the final diecast car meets all design and quality standards. This stage is essential for verifying the design’s accuracy and making any necessary modifications before moving to the more expensive mass production phase.

Material Selection

Selecting the right materials is paramount in manufacturing high-quality NASCAR diecast cars. The primary material used for the body of the car is zinc alloy, often referred to as Zamak. This material is chosen for its excellent die-casting properties, durability, and ability to capture fine details. Other materials, such as plastic, are used for interior components, tires, and other parts where flexibility or specific properties are required. The careful selection of these materials ensures that the final product is not only aesthetically pleasing but also durable and capable of withstanding the test of time. The materials must meet rigorous standards to guarantee the longevity and quality of the diecast car, making it a valuable collectible item.

Zinc Alloy Casting

Die Creation

Die creation is the critical step in preparing for the zinc alloy casting process. This involves manufacturing high-precision molds, or dies, which will be used to shape the molten zinc alloy into the various components of the diecast car. These dies are typically made of hardened steel and are designed with intricate details to replicate the design’s complexity. The accuracy and quality of the dies are crucial, as they directly impact the final product’s accuracy and quality. Skilled engineers and technicians meticulously craft these dies, ensuring they can withstand the extreme temperatures and pressures of the casting process. The dies are an investment, as they can be used to produce thousands of diecast cars. They require precision engineering to produce the detailed and accurate components of the diecast model.

Casting Process

The casting process begins once the dies are ready. Molten zinc alloy is injected into the dies under high pressure, filling every detail and crevice. The high pressure ensures that the molten metal precisely captures the intricate details of the die, resulting in sharp edges and fine surface finishes. After the metal cools and solidifies, the dies open, and the newly cast components are extracted. This process is repeated for various parts, such as the car’s body, chassis, and engine components. The efficiency and precision of the casting process are essential in producing large quantities of diecast cars while maintaining high quality. The ability to create complex shapes and fine details with accuracy is a hallmark of the die-casting technique. The process is meticulously controlled to ensure consistency and minimal defects in the finished products.

Preparation for Painting

Once the diecast components are cast, they undergo a thorough preparation phase for painting. This is a crucial step that ensures the paint adheres correctly to the metal surface and achieves a flawless finish. Preparation involves several stages, including surface cleaning, smoothing, and priming. Surface cleaning removes any impurities or residues from the casting process, while smoothing eliminates any imperfections or rough spots. A primer is then applied, which creates a receptive surface for the paint, enhancing adhesion and durability. This meticulous preparation ensures that the subsequent painting process results in a high-quality, long-lasting finish. Each step is carefully executed to ensure that the paint adheres smoothly and evenly, enhancing the car’s overall visual appeal and longevity.

Surface Preparation

Surface preparation is essential for achieving a smooth and professional paint finish. The diecast components undergo careful cleaning and degreasing to remove any contaminants that might interfere with paint adhesion. This process is often performed using specialized cleaning solutions and techniques. Once cleaned, the surfaces are inspected for any imperfections, such as burrs or rough edges, which are then smoothed out using abrasive tools or techniques. A high-quality surface finish is crucial because it ensures that the paint adheres evenly and that any detail, such as panel lines or logos, will appear sharp and clear. This step creates an ideal surface for the application of the base coat, setting the stage for a visually appealing and durable diecast car.

Base Coating

After the surface preparation, the diecast car components are ready for base coating. This step involves applying a layer of primer or base paint to the metal surfaces. The base coat acts as a foundation for the subsequent paint layers and provides a smooth, even surface for the application of the final color. The base coat also protects the metal from corrosion and enhances the paint’s adhesion, ensuring it lasts longer. The base coating process is carried out in a controlled environment, such as a spray booth, to ensure an even and consistent application. The use of high-quality base coats and the controlled environment contribute to the overall aesthetic and durability of the diecast car. This initial coat sets the color tone and establishes a uniform surface, ready for the detailed graphics and designs that follow.

Applying Decals

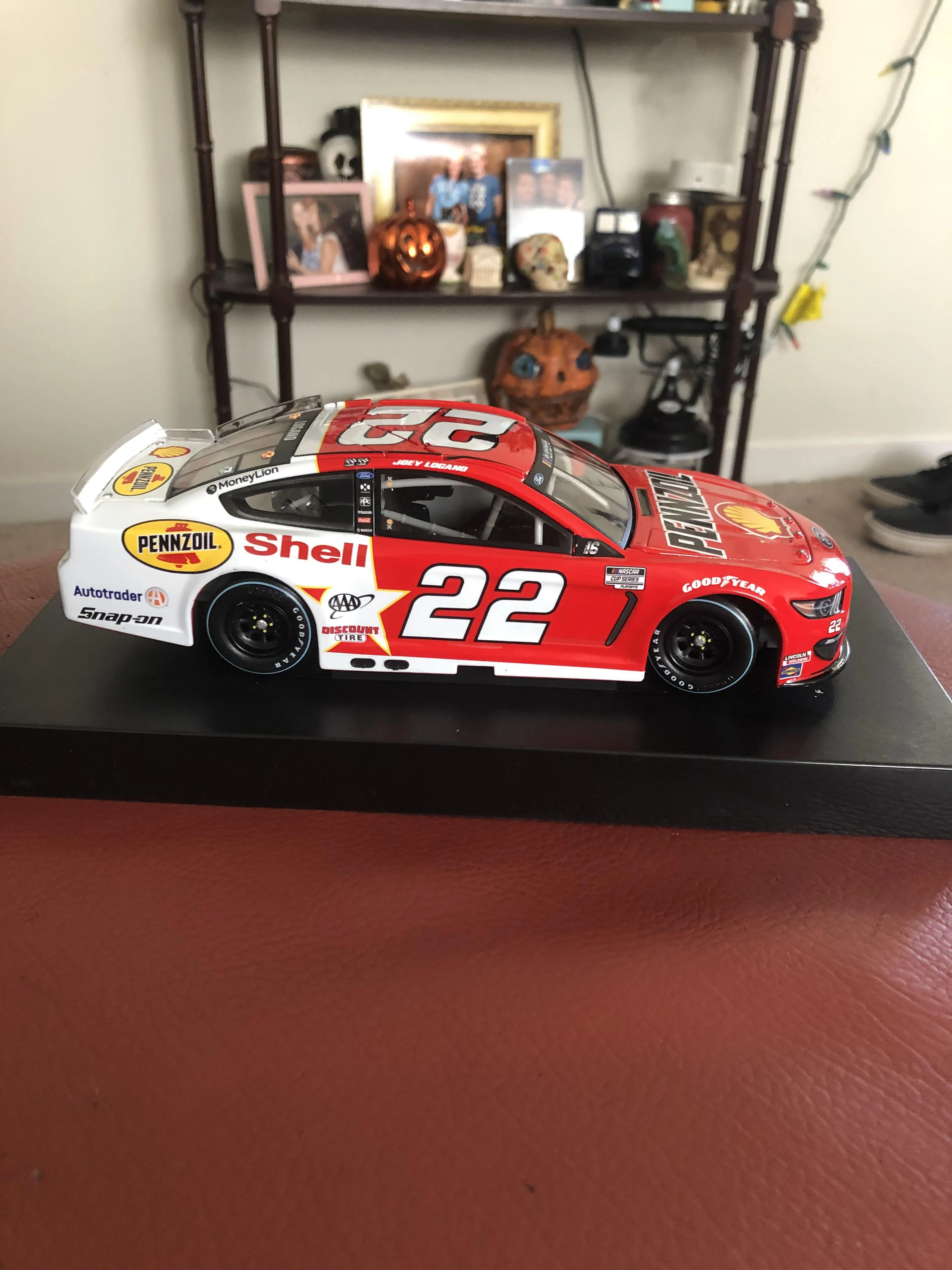

Applying decals is a crucial step in bringing the diecast car to life, reproducing the intricate designs and sponsor logos seen on real NASCAR race cars. These decals are printed on specialized materials and applied with precision to ensure accurate representation. The application of decals is often done by skilled technicians who carefully position and adhere the decals to the car’s surface. The process involves precise alignment and smoothing to eliminate air bubbles and ensure that the decals conform to the car’s curves and details. This meticulous attention to detail enhances the realism and authenticity of the diecast model. The quality of the decals and the skill of their application significantly impact the final appearance of the car, making this step vital for collectors and enthusiasts.

Decal Application Techniques

Various techniques are employed for applying decals to diecast cars. These techniques range from manual application to automated processes, depending on the complexity of the design and the scale of production. For smaller productions or highly detailed designs, skilled technicians use tweezers, applicators, and specialized tools to carefully position and adhere the decals. The decals are often pre-cut and arranged to ensure accurate placement. In large-scale manufacturing, automated decal application systems may be used to increase efficiency and ensure consistency. Regardless of the method, the aim is always to ensure that the decals are accurately aligned, bubble-free, and firmly attached to the surface. The selection of techniques depends on the level of detail and production volume required.

Clear Coating

Once the decals are applied, the diecast car undergoes a clear coating process. This involves applying a transparent protective layer over the entire car. The clear coat serves multiple purposes: it protects the paint and decals from damage, provides a glossy finish, and enhances the car’s overall appearance. The clear coat also makes the car more resistant to scratches, UV rays, and other environmental factors. The application of the clear coat must be done evenly and consistently to avoid imperfections. Skilled technicians often use spray booths to ensure a smooth, professional finish. The clear coat is crucial in enhancing the car’s visual appeal and protecting its finish, contributing to the overall longevity and value of the diecast car for collectors and enthusiasts.

Assembly Process

The assembly process is where all the individual components come together to form the complete diecast car. This intricate step involves attaching the various parts, such as the chassis, engine, interior, wheels, and other accessories. Skilled technicians use specialized tools and techniques to ensure each component is correctly positioned and securely fastened. Careful attention is given to detail, guaranteeing that every element aligns perfectly and functions as intended. The assembly process requires precision and expertise to replicate the real race car’s appearance accurately. The quality of the assembly directly affects the overall look and durability of the finished diecast car, making it a critical part of the manufacturing process.

Parts Assembly

Parts assembly is the culmination of the manufacturing process, bringing together all the pre-cast, painted, and detailed components. This includes attaching the chassis to the body, installing the interior, mounting the wheels, and affixing any additional accessories, such as spoilers, mirrors, and antennas. Technicians employ various methods, including screws, adhesives, and snap-fit designs, to ensure that all parts are securely attached. During this step, extreme care is taken to align the components correctly, ensuring that the car’s proportions and appearance match the original race car. Skilled assemblers pay close attention to detail, checking for any imperfections or misalignments. This phase is where the diecast model takes its final form, making it a precise and vital process for creating a realistic and attractive collectible item.

Quality Control

Quality control is integrated throughout the entire manufacturing process. Multiple inspection points are in place to ensure that each diecast car meets the highest standards of quality and accuracy. This involves visual inspections, dimensional checks, and functional tests to identify any defects or imperfections. The inspection ensures that the product accurately replicates the real NASCAR car. Quality control teams assess the paint finish, decal application, assembly, and overall appearance of each car. Cars that fail to meet the set standards are either reworked or rejected, ensuring that only flawless products reach the market. This stringent quality control process is essential in maintaining the reputation and value of the diecast cars, offering collectors and enthusiasts a high-quality product.

Final Inspection

The final inspection is the last step in the quality control process. During this phase, the fully assembled diecast cars undergo a thorough evaluation to ensure they meet all quality standards and design specifications. Trained inspectors meticulously examine each car for any remaining defects, such as paint imperfections, misaligned decals, or assembly errors. They also check for functionality, ensuring that all moving parts, such as wheels and steering, operate smoothly. Cars passing the final inspection are packaged and prepared for distribution, while those that fail are either sent back for rework or rejected. This final check guarantees that the diecast cars delivered to collectors are of the highest quality, reflecting the precision and dedication that goes into their production. The final inspection is a critical step in maintaining the product’s integrity and satisfying the expectations of customers.