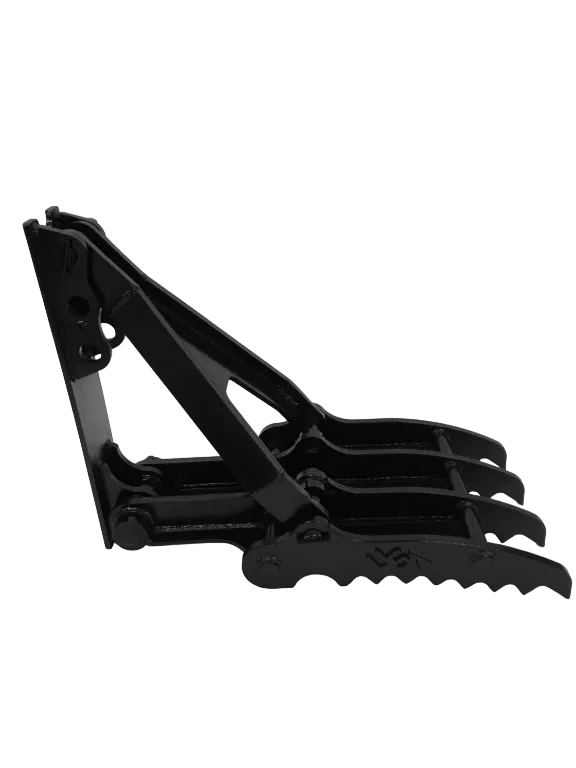

What is an Excavator Thumb?

An excavator thumb is a crucial attachment for excavators, designed to work in tandem with the excavator’s bucket. This attachment functions as a ’thumb,’ allowing the bucket to grab and secure objects, enhancing the excavator’s ability to handle a wide range of materials and tasks. It essentially transforms the excavator into a giant, versatile hand, greatly improving its efficiency and productivity on construction sites and in various earthmoving operations. The design and functionality of an excavator thumb can vary, but the core purpose remains consistent: to provide a secure grip for lifting, carrying, and placing objects.

The Purpose of an Excavator Thumb

The primary purpose of an excavator thumb is to increase the versatility and efficiency of an excavator. By providing a clamping action, the thumb allows the excavator to grasp and manipulate irregularly shaped objects, such as rocks, logs, and debris, that would be difficult or impossible to handle with just the bucket alone. This capability reduces the need for manual labor, streamlines operations, and reduces the risk of accidents on the job site. Excavator thumbs are essential attachments for tasks that demand precision and control when handling various materials, making them invaluable tools in modern construction and landscaping projects.

Key Feature One Enhanced Gripping Power

One of the most important features of an excavator thumb is its enhanced gripping power. The design of the thumb, combined with the bucket, creates a secure clamping action that can hold objects firmly in place. This gripping power is crucial for lifting heavy or awkwardly shaped items without them slipping or falling. A well-designed excavator thumb will distribute the clamping force evenly, minimizing the risk of damaging the material being handled and ensuring a stable and safe operation. This is particularly important when dealing with heavy objects, where a strong grip is essential for preventing accidents.

Benefits of Superior Gripping

Superior gripping offers several benefits on the job site. Primarily, it improves safety by reducing the risk of dropped loads, which can cause injuries or damage. Furthermore, enhanced gripping power increases efficiency by allowing operators to move more materials in less time, leading to higher productivity. It also reduces the amount of manual labor needed, allowing workers to focus on other tasks. The ability to handle a wider variety of materials with greater control also opens up more project opportunities, making the excavator a more versatile and valuable piece of equipment for any contractor.

Applications of Strong Gripping

Strong gripping is essential in various applications. It’s crucial when handling large rocks or boulders during land clearing or landscaping projects. In demolition, it helps in safely removing and loading debris. Construction sites benefit greatly from this feature, as it aids in the handling of pipes, concrete blocks, and other construction materials. Forestry operations use it to move logs and branches with ease. Overall, the applications are extensive, making the excavator thumb a versatile tool for any project requiring secure material handling.

Key Feature Two Increased Versatility

Another key feature of an excavator thumb is its ability to increase the versatility of the excavator. By adding a clamping function, the thumb significantly expands the range of tasks an excavator can perform. Instead of being limited to digging and scooping, an excavator equipped with a thumb can now handle various materials, from logs and pipes to demolition debris and irregularly shaped objects. This versatility translates into reduced equipment needs, increased efficiency, and the ability to undertake a wider range of projects, making the excavator a more valuable asset on any job site.

Versatility in Action: Common Tasks

The versatility of an excavator thumb is evident in its ability to perform various tasks. It’s commonly used for moving and placing large rocks in landscaping projects, efficiently handling logs and branches in forestry applications, and carefully moving demolition debris in construction sites. In addition, it assists in sorting and loading materials, such as separating recyclable materials from general waste. Its capacity to handle diverse materials makes the excavator a versatile tool, reducing the need for specialized equipment and streamlining project workflows.

Benefits of Versatility

The versatility of an excavator thumb offers several benefits. It reduces the need for additional equipment, minimizing costs and logistical complexities. It enhances productivity by enabling operators to complete a wider range of tasks with a single machine. The excavator can handle a variety of materials with ease, reducing the need for manual labor and increasing efficiency. Furthermore, this versatility allows contractors to bid on a wider range of projects, increasing their business opportunities and profitability. Overall, versatility is a critical feature for any excavator thumb.

Key Feature Three Enhanced Safety

Safety is a crucial aspect of using an excavator thumb. The primary function of the thumb is to enhance safety by providing a secure grip on materials, reducing the risk of dropped loads and potential injuries. By clamping objects in place, the thumb minimizes the chance of items slipping or shifting during transport, especially on uneven terrain. A properly designed and installed thumb contributes to a safer work environment, allowing operators to handle materials with greater confidence and control. Regular inspection and maintenance of the thumb are essential to ensure it continues to function safely.

Safety Considerations When Using an Excavator Thumb

When using an excavator thumb, several safety considerations are important. Always inspect the thumb and bucket for any signs of damage or wear before operation. Ensure that the thumb is properly attached and secured to the excavator. Never exceed the excavator’s weight capacity when lifting or carrying materials. Be mindful of the surrounding environment, including overhead power lines and other potential hazards. Operate the excavator at a safe speed, especially when handling heavy or unstable objects. Provide proper training to all operators and enforce safe operating procedures to minimize the risk of accidents and injuries.

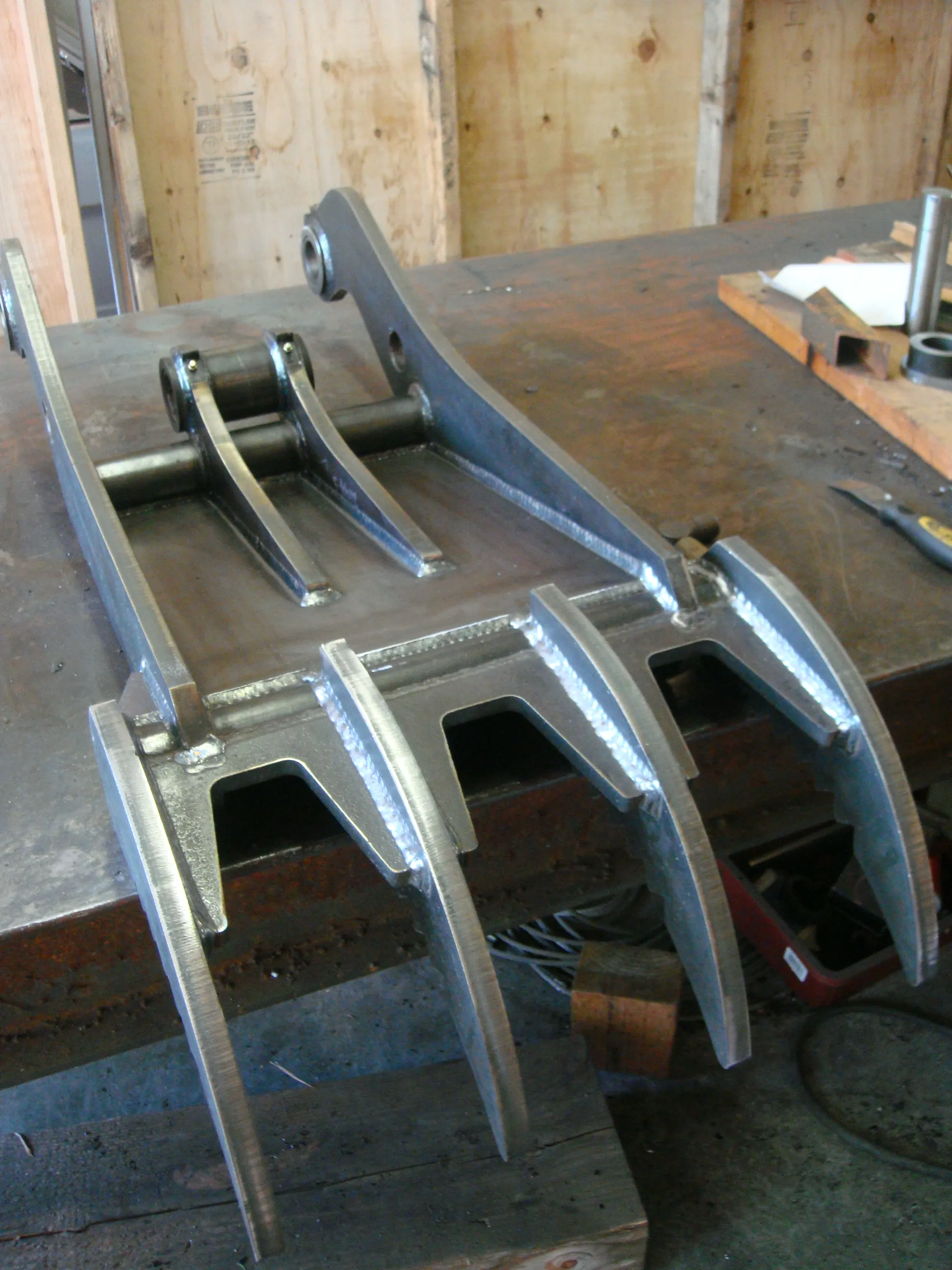

Key Feature Four Durability and Construction

The durability and construction of an excavator thumb are vital for its performance and lifespan. A well-constructed thumb will be made from high-quality, robust materials, typically steel, designed to withstand the rigorous demands of heavy-duty use. The welds and joints should be strong and precise to handle the stresses of lifting and carrying heavy loads. The design should also consider the type of tasks the thumb will perform, with features like reinforced plates and wear-resistant surfaces to extend its life. Investing in a durable excavator thumb ensures it can withstand tough conditions, minimize downtime, and provide a reliable performance over time.

Materials and Construction Quality

High-quality materials and construction are crucial for the durability of an excavator thumb. The thumb should be constructed from durable steel grades, often with reinforced components at stress points. The welds should be strong and continuous, and the overall design should minimize stress concentrations. Wear-resistant materials, like hardened steel or abrasion-resistant coatings, should be used in high-wear areas. The thumb should be designed for easy maintenance, with accessible grease points and replaceable wear parts. A well-built thumb ensures it can endure the demands of various applications, providing a long service life and reducing maintenance costs.

Key Feature Five Easy Installation and Compatibility

Easy installation and compatibility are essential features of an excavator thumb. A well-designed thumb should be easy to install on a variety of excavator models without extensive modifications. It should come with clear and comprehensive installation instructions. Compatibility ensures that the thumb fits correctly with the excavator’s bucket and hydraulic system. Compatibility is usually determined by factors like the excavator’s weight class, bucket size, and pin configuration. A thumb that is easy to install and compatible with the excavator reduces downtime and enables operators to get the attachment up and running quickly, improving productivity.

Factors in Compatibility

Several factors influence the compatibility of an excavator thumb. The primary consideration is the excavator’s weight class and bucket size. The thumb must be appropriately sized and rated to handle the excavator’s capacity. The pin configuration of the excavator bucket is also important, as the thumb is often mounted using the same pins. The hydraulic system must be compatible to operate the thumb’s cylinder. Manufacturers typically provide detailed compatibility charts that list the excavator models the thumb is designed to fit. Checking these details ensures a correct fit and safe operation.

Summary The Essential Features

In summary, an excavator thumb is a valuable attachment for any construction or earthmoving project. The top 5 features to consider are enhanced gripping power for secure handling, increased versatility to handle various materials, enhanced safety through secure clamping, durable construction for longevity, and easy installation with broad compatibility. These features combine to make the excavator more efficient, versatile, and safe, ultimately improving productivity and reducing operational costs. When selecting an excavator thumb, carefully evaluate these key features to choose the best attachment for your specific needs and applications.