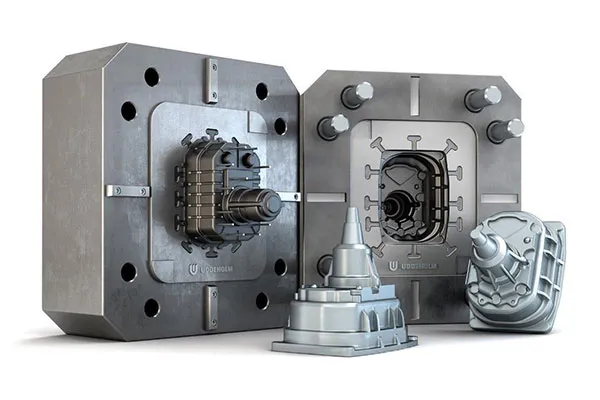

What is Diecast Material?

Diecast material refers to the metals and alloys specifically used in the die casting process. Die casting is a manufacturing process that involves injecting molten metal under high pressure into reusable molds, known as dies. This technique allows for the creation of complex shapes with high precision and excellent surface finishes. The choice of material is crucial, as it significantly impacts the final product’s properties, including strength, weight, corrosion resistance, and cost-effectiveness. Various materials can be die cast, each offering unique advantages for different applications. Understanding the different diecast materials is essential for manufacturers to optimize product design and performance, ensuring they select the most suitable material for their specific needs. This selection process involves careful consideration of the mechanical, chemical, and thermal properties of each alloy.

The Composition of Diecast Materials

The composition of diecast materials varies widely, with the most common metals being aluminum, zinc, and magnesium alloys. Each of these metals can be mixed with other elements to enhance specific properties. For example, adding silicon to aluminum alloys improves fluidity, allowing for more complex designs and better surface finishes. Zinc alloys often include aluminum and copper, which increase strength and corrosion resistance. Magnesium alloys are frequently alloyed with aluminum, zinc, and manganese, to enhance mechanical characteristics. These alloying elements are carefully chosen to optimize the material’s performance within the die casting process. The precise formulation of a diecast material is crucial, as it directly influences the final product’s characteristics, impacting factors such as strength, durability, and resistance to environmental factors. Understanding the composition of these materials is the first step to making the best possible selection for any die casting project.

Aluminum Alloys in Die Casting

Aluminum alloys are a popular choice in die casting due to their excellent strength-to-weight ratio, good corrosion resistance, and high thermal conductivity. These properties make them suitable for a broad range of applications, particularly in the automotive and aerospace industries. Common aluminum alloys used in die casting include those from the A380 and A360 series. Silicon and copper are often added to improve the alloy’s castability and mechanical properties. The resulting components are lightweight and can withstand high operating temperatures, which is crucial for engine components and other parts exposed to extreme conditions. Furthermore, the ability of aluminum alloys to be easily finished through processes like anodizing makes them versatile for aesthetic and functional applications. Aluminum die casting is frequently chosen when design requires both strength and a lightweight material.

Zinc Alloys for Die Casting

Zinc alloys offer a unique combination of properties that make them an excellent choice for specific applications. They are known for their high dimensional accuracy, good castability, and ability to produce intricate shapes. These alloys are also relatively inexpensive compared to other diecast materials, making them a cost-effective option for mass production. Zinc alloys typically include additions of aluminum, copper, and magnesium to improve their mechanical properties and corrosion resistance. The low melting point of zinc allows for faster production cycles and extended die life, contributing to overall cost savings. Zinc die castings are widely used in the automotive, hardware, and electronics industries where precision and affordability are key requirements. Moreover, zinc’s ability to provide a smooth surface finish makes it ideal for components that require plating or other surface treatments.

Magnesium Alloys in Die Casting

Magnesium alloys are valued for their exceptional strength-to-weight ratio, making them a preferred choice in applications where weight reduction is critical. They are lighter than aluminum alloys and exhibit good mechanical properties, allowing for thinner wall sections and more compact designs. Magnesium alloys are commonly alloyed with aluminum, zinc, and manganese to enhance their strength, corrosion resistance, and creep resistance. Despite their benefits, magnesium alloys have a higher cost compared to zinc and aluminum. They also require specific handling and processing due to their reactivity. Magnesium die castings are primarily used in the automotive and aerospace industries for parts such as instrument panels, engine components, and structural elements. These alloys are also used in portable electronic devices, where minimizing weight while maintaining structural integrity is essential. The growing use of magnesium alloys underscores the importance of lightweight materials in modern engineering.

Top 5 Uses of Diecast Material

Automotive Components

The automotive industry is a major consumer of diecast materials. Aluminum and zinc alloys are extensively used to manufacture engine blocks, transmission housings, and various structural components. The high strength-to-weight ratio of these materials helps improve fuel efficiency and overall vehicle performance. Die casting allows for the complex geometries required in modern engine designs, optimizing both performance and cooling efficiency. Furthermore, diecast components are cost-effective for mass production, making them ideal for the high volumes demanded by the automotive sector. The adoption of diecast materials in automotive production is growing as manufacturers prioritize lightweight, high-performance components to meet stricter emission standards and improve vehicle efficiency. This trend includes wider use in electric vehicles as well, for components like battery housings.

Consumer Electronics

The consumer electronics sector heavily relies on diecast materials for manufacturing housings, frames, and internal components of devices such as smartphones, laptops, and tablets. Aluminum and magnesium alloys are favored for their lightweight and aesthetic appeal. Die casting enables the creation of sleek, durable designs with precise dimensions, essential for the compact and sophisticated devices consumers demand. These materials also provide excellent heat dissipation, which is critical for the long-term performance of electronic devices. The ability to incorporate intricate designs and features, such as integrated mounting points and thin-wall construction, further enhances the versatility of diecast materials in the consumer electronics industry. The rapid pace of technological innovation ensures that die casting will continue to play a crucial role in this sector.

Industrial Machinery

Industrial machinery, including pumps, compressors, and power tools, frequently utilizes diecast components due to their durability, strength, and dimensional accuracy. Aluminum, zinc, and occasionally magnesium alloys are used to produce housings, gears, and other parts that must withstand demanding operating conditions. Die casting provides the necessary precision to ensure the proper fit and functionality of these components, while also providing the strength needed for long-term use. The high production rates possible with die casting meet the demands of industrial manufacturing, contributing to efficient and cost-effective production runs. The ability to integrate complex designs and features directly into the casting, reduces the need for secondary machining operations. This results in streamlined manufacturing processes and reduced costs, making die casting a prime choice for many industrial applications.

Aerospace Parts

The aerospace industry leverages diecast materials for components where high strength, lightweight properties, and reliability are paramount. Aluminum and magnesium alloys are common choices, particularly for structural parts, housings, and engine components in aircraft and spacecraft. Die casting allows for the production of complex geometries with tight tolerances, meeting the rigorous demands of aerospace engineering. The ability to create parts with exceptional dimensional accuracy and excellent surface finishes is essential for ensuring the performance and safety of aerospace vehicles. While the initial cost of die casting can be high, the resulting weight savings and enhanced performance make it a cost-effective option over time, especially when combined with the reduced need for post-processing. The continual evolution of aerospace technology means the application of diecast materials will remain vital.

Hardware and Tools

Diecast materials, particularly zinc and aluminum alloys, are widely used in the manufacturing of hardware and tools. These materials provide the necessary strength, durability, and corrosion resistance required for the demanding environments in which these products are used. Die casting allows for intricate designs, making it possible to create complex shapes and features in tools such as wrenches, pliers, and hammers. The process also ensures dimensional consistency, crucial for parts that need to fit together precisely. The cost-effectiveness and speed of production associated with die casting make it an ideal choice for manufacturers looking to produce high-quality tools at competitive prices. Furthermore, diecast parts are often suitable for plating and surface treatments, further enhancing their appearance and performance, making them a great option for both professional and DIY tools.

Benefits of Using Diecast Material

High Production Rates and Efficiency

Die casting offers high production rates, making it an efficient manufacturing process for mass production. The rapid cycle times, where molten metal is injected into a die and solidifies quickly, enable manufacturers to produce large quantities of parts in a short amount of time. This high efficiency translates to reduced production costs and quicker turnaround times. The ability to create complex parts with minimal post-processing further enhances this efficiency, saving time and resources. Furthermore, the automation of die casting processes ensures consistent quality and reduces the need for manual labor, optimizing the manufacturing workflow. The overall productivity boost makes die casting an ideal choice for industries that require large-scale production volumes while maintaining high quality and precision.

Complex Designs and Geometry

Die casting excels at creating complex designs and intricate geometries that are difficult or impossible to achieve with other manufacturing processes. The ability to incorporate fine details, thin walls, and complex shapes allows designers to create highly functional and aesthetically pleasing products. This flexibility is particularly beneficial in industries such as automotive and electronics, where intricate designs are often required. The use of specialized dies and advanced die casting techniques enables the production of parts with undercuts, internal features, and integrated mounting points. This capability eliminates the need for multiple manufacturing steps, streamlining the production process and reducing costs. The ability to create complex designs opens up vast opportunities for innovation in product development and design.

Excellent Dimensional Accuracy

Die casting provides exceptional dimensional accuracy, ensuring parts meet the required specifications and fit together seamlessly. The process allows for tight tolerances, minimizing variations in dimensions and ensuring consistent product quality. This precision is crucial for components that require precise mating and functionality, such as gears, housings, and connectors. The ability to achieve high dimensional accuracy reduces the need for secondary machining operations and minimizes the risk of defects. It also contributes to improved product performance and reliability. The precision offered by die casting makes it suitable for industries where even minor deviations can impact the final product’s functionality. It therefore plays an important role in maintaining high standards across a wide range of applications.

Cost-Effectiveness in Mass Production

Die casting is a cost-effective manufacturing process, especially for large-scale production runs. While the initial investment in tooling can be significant, the high production rates and minimal post-processing requirements lead to lower per-unit costs. The automated nature of die casting reduces labor costs and ensures consistent quality. The efficient use of materials and the ability to create net-shape or near-net-shape components further contribute to cost savings. The process also reduces the need for extensive machining and finishing operations, simplifying the manufacturing process. Die casting enables manufacturers to achieve economies of scale, making it an ideal choice for producing large volumes of parts at competitive prices. The long lifespan of the dies also contributes to the overall cost-effectiveness of the die casting process.

Material Strength and Durability

Diecast materials exhibit excellent strength and durability, making them suitable for applications that require robust performance. The high-pressure injection of molten metal into the die results in parts with a fine grain structure and improved mechanical properties. This gives the cast components the ability to withstand high stresses and resist wear and tear. Diecast parts also tend to be resistant to impacts, vibration, and other environmental factors. The materials used in die casting can be selected and alloyed to provide the desired strength, hardness, and resistance to corrosion. This makes the process well-suited for creating components that need to perform reliably in challenging environments, ensuring a long lifespan and reducing the need for frequent replacement.

Choosing the Right Diecast Material

Factors to Consider

Choosing the right diecast material involves careful consideration of several factors. The intended application, the required mechanical properties, and the desired level of corrosion resistance are paramount. The operating environment of the component, including temperature, humidity, and exposure to chemicals, must also be considered. Cost is another crucial factor; the price of the material and the complexity of the casting process will impact the overall expense. Production volume is important, as the choice of material can affect the efficiency and cost-effectiveness of the die casting process. Furthermore, the desired surface finish and any post-processing requirements influence material selection. A thorough evaluation of these factors ensures that the selected diecast material meets the performance requirements while remaining cost-effective.

Mechanical Properties

Mechanical properties, such as tensile strength, yield strength, elongation, and hardness, are critical in selecting a diecast material. The material must be strong enough to withstand the stresses and loads it will encounter during use. Yield strength indicates the amount of stress a material can endure without permanent deformation, while tensile strength defines the maximum stress the material can handle before breaking. Elongation measures the material’s ability to stretch or deform before failure, and hardness indicates its resistance to surface indentation. The operating environment may also influence the choice; elevated temperatures can reduce the strength of certain alloys. Understanding the mechanical properties of various diecast materials enables engineers to choose a material that can ensure the component’s performance and longevity. The mechanical properties must be in harmony with the application’s specific demands.

Corrosion Resistance

Corrosion resistance is a critical factor, especially for components exposed to moisture, chemicals, or other corrosive environments. The chosen diecast material should be able to withstand the specific corrosive agents without significant degradation. Aluminum alloys generally offer good corrosion resistance, particularly when properly finished or treated. Zinc alloys also exhibit reasonable corrosion resistance, but this can be enhanced through alloying with copper or other elements. Magnesium alloys have lower corrosion resistance compared to aluminum, but this can be improved with surface treatments. Factors such as the type of environment, the presence of galvanic couples with other materials, and the required service life of the component influence the need for corrosion-resistant materials. The selection of appropriate alloys and coatings is necessary to ensure the durability and reliability of the diecast part over its intended lifespan.

Cost Considerations

Cost is an essential element of diecast material selection, encompassing the cost of the material itself, the manufacturing process, and any post-processing requirements. Aluminum alloys are generally more expensive than zinc alloys, while magnesium alloys tend to be the most costly. The complexity of the casting, including part design and required tolerances, impacts the tooling costs and production efficiency. Production volumes also affect the overall cost; large production runs spread the initial tooling costs over more units, reducing the per-unit expense. The cost of finishing operations, such as machining, plating, or painting, should be taken into account. A thorough cost analysis must consider all factors, allowing manufacturers to select the most cost-effective material and process that meets their performance requirements. A balance between material properties, production efficiency, and overall budget is necessary for achieving the best value.

Surface Finish Requirements

Surface finish requirements are often an important consideration in the selection of diecast materials. The desired appearance, texture, and functionality of the final product will determine the appropriate material. Some materials, like zinc, offer excellent surface finishes straight from the die, which reduces the need for post-processing. Others, like aluminum, may require additional treatments, such as polishing, painting, or anodizing, to achieve the desired finish. The required level of surface finish depends on the application and aesthetic preferences. For example, automotive parts may require a smooth, high-gloss finish, while industrial components may prioritize durability and corrosion resistance. The compatibility of the material with different finishing processes should also be considered. A proper understanding of surface finish requirements helps ensure that the final product meets both functional and aesthetic expectations.